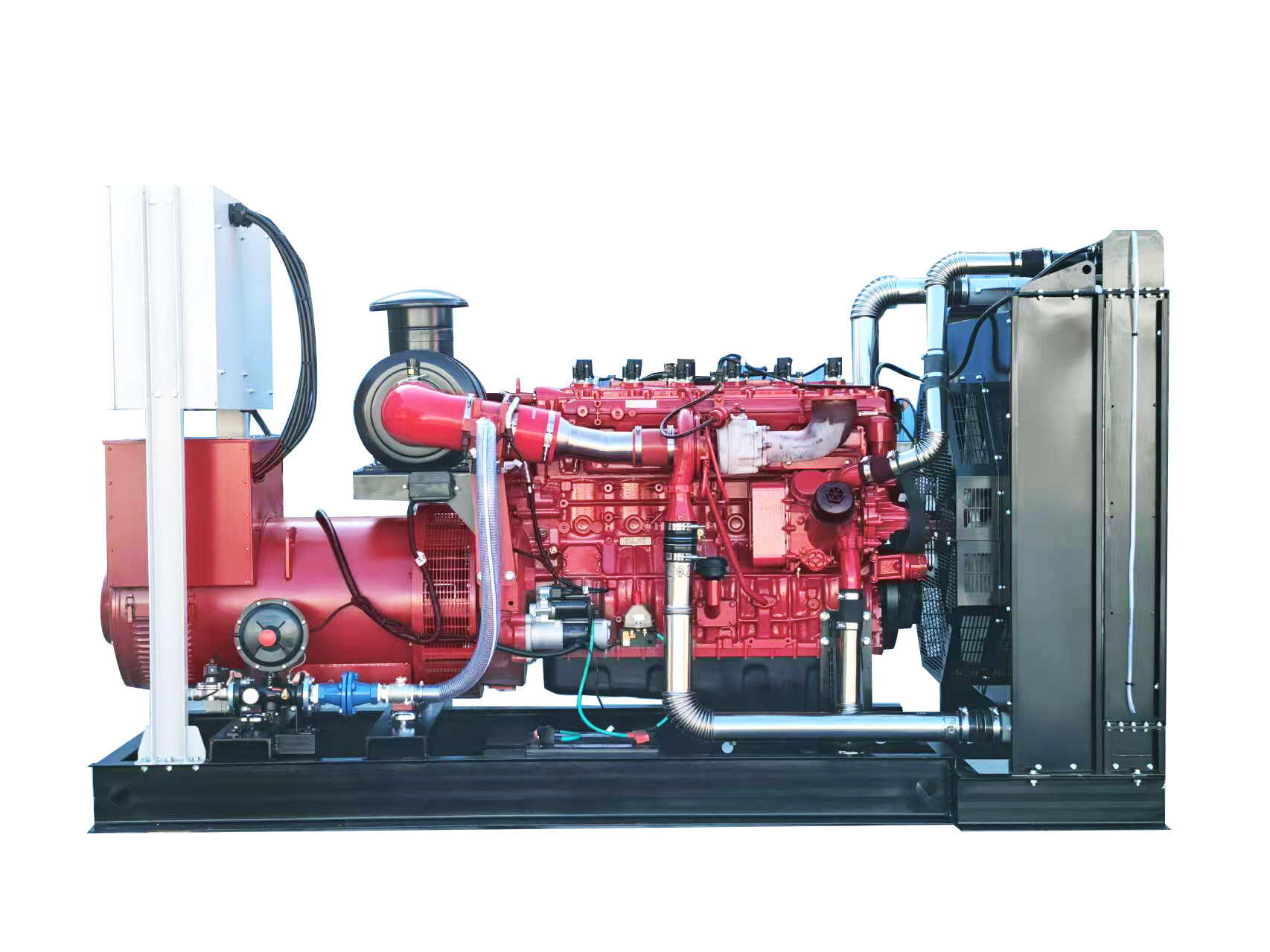

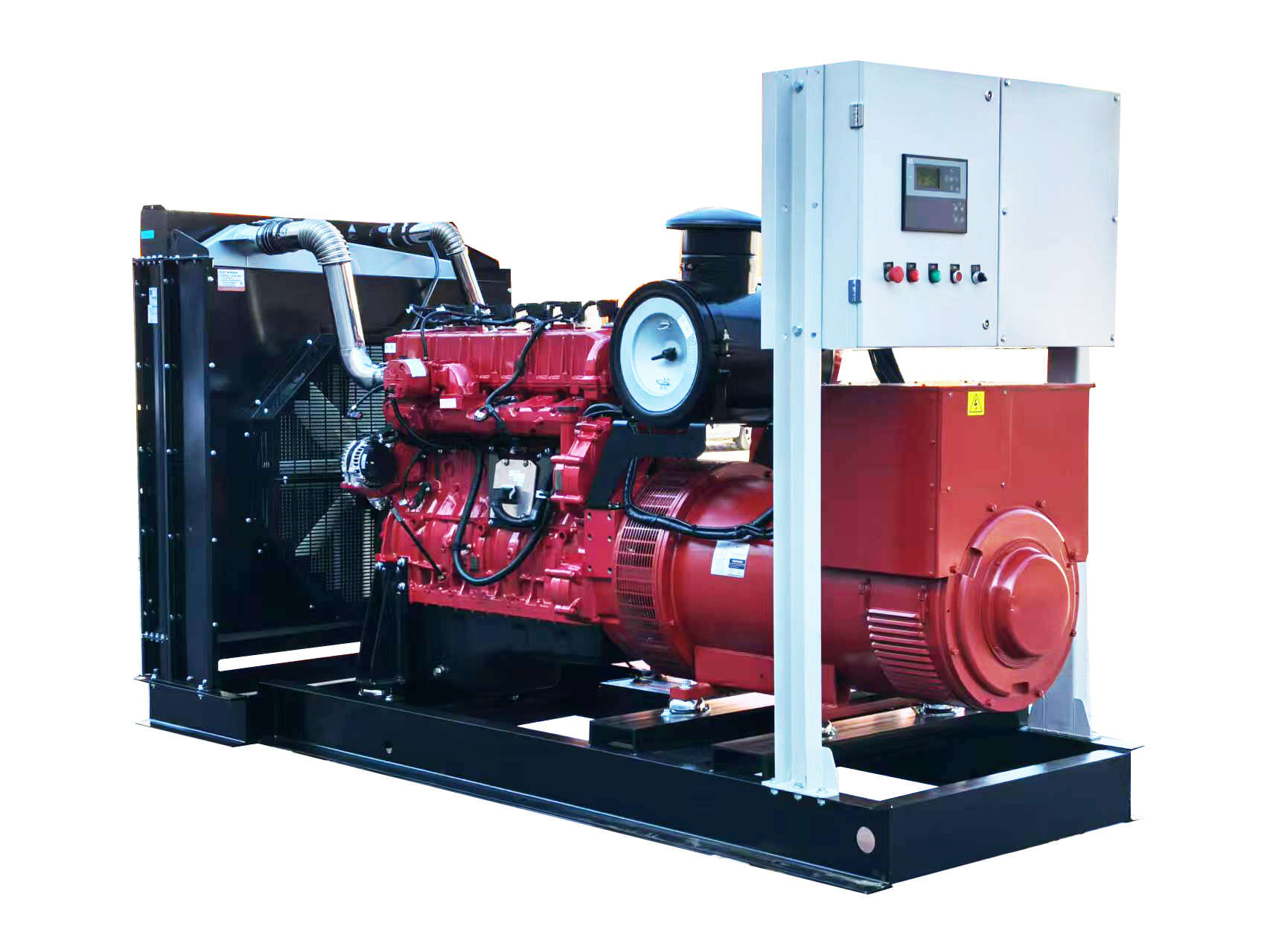

Low energy consumption and high efficiency 300KW natural gas generator set

The Leiteng LT-300GF Natural Gas Generator Unit is an advanced power solution designed for reliable and efficient operation. With a capacity of 300GF, this generator is ideal for both residential and commercial applications where stable electricity supply is crucial. It features a robust design that supports long hours of continuous use, ensuring dependable power during outages or as a primary energy source. The unit is equipped with cutting-edge technology for optimal performance, including automatic operation capabilities, which enhance convenience and reduce labor costs. Additionally, the LT-300GF adheres to environmental standards, offering cleaner and more sustainable power generation with natural gas. Its user-friendly interface and compact design make installation and maintenance straightforward, providing peace of mind for users seeking a high-quality generator solution.

- Overview

- Related Products

Core Benefits

Environmentally friendly (relatively clean):

Low emissions: Combustion of natural gas produces significantly fewer pollutants than coal and diesel. Carbon dioxide emissions are about 50 per cent less than coal and about 30 per cent less than oil. Emissions of nitrogen oxides, sulphur oxides and particulate matter are also much lower than coal and diesel.

No Soot/Ash: Combustion produces virtually no soot or ash, reducing the need to dispose of solid waste.

Fuel Cost and Availability:

Relative Economics: In areas where natural gas is abundant and pipeline infrastructure is well established, natural gas is often more affordable than liquid fuels such as diesel (especially if piped gas is available).

Stability of supply (piped gas): Natural gas delivered by pipeline is generally more stable and reliable than diesel fuel, which requires frequent transport and storage (provided the pipeline network is well established).

Operational performance:

Fast start-up and response: Gas gensets typically have a short start-up time and fast load response, making them ideal for back-up power or peak shifting.

Smooth operation and low noise: natural gas combustion process is relatively smooth, vibration and noise is usually less than the same power of diesel generator sets.

Lower maintenance costs (relative to some types): Natural gas burns cleaner and produces less carbon and lubricant contamination, so spark plugs, piston rings, lubricants, etc. may have relatively longer replacement intervals and relatively less maintenance (especially compared to heavy fuel oil or coal).

Efficiency:

Higher efficiencies: Modern natural gas-fired generating sets (particularly gas internal combustion engines and gas turbines) have high efficiencies for power generation. Gas combustion engines typically have efficiencies of around 35-45 per cent, with high efficiency units reaching 48 per cent or more. Gas turbines have a wide range of efficiencies, from about 30-40 per cent for simple cycles to more than 60 per cent for combined cycles.

High potential for cogeneration: Natural gas generators are well suited for cogeneration. With their high exhaust and cylinder liner water temperatures and high waste heat recovery efficiency, they can generate both electricity and useful heat (steam or hot water), increasing the combined energy use efficiency to 70%-90%, significantly improving economy and environmental protection.

Fuel Flexibility:

Some units are designed to be compatible with a wide range of gaseous fuels, such as biogas, coal bed methane, landfill gas, petroleum associated gas, etc., which improves the flexibility of resource utilisation.

Core Disadvantages and Challenges

High dependence on infrastructure:

Pipeline constraints: The biggest limitation is the need to connect to the natural gas pipeline network. In areas where pipelines are not available, the use of LNG or CNG can add significant cost and complexity.

LNG/CNG storage and transport: The use of LNG or CNG requires specialised cryogenic tanks or high-pressure cylinders, as well as corresponding transport and filling facilities, which increase initial investment and operating costs, and can pose safety risks (which need to be strictly regulated).

Initial investment costs:

The purchase cost of the natural gas genset itself is usually higher than that of a diesel genset of the same power. If a natural gas connection facility (regulator station, etc.) or LNG/CNG storage and refuelling system also needs to be constructed, the initial investment will be even higher.

Fuel cost volatility:

The price of natural gas is highly influenced by market supply and demand, geopolitics and other factors, and there is a risk of fluctuation. During periods of high gas prices, the operating cost advantage may diminish or even disappear.

Slightly lower efficiency relative to diesel (simple cycle only):

In simple power generation applications (not cogeneration), modern high-speed diesel generator sets of the same level of technology typically generate electricity at slightly higher efficiencies than natural gas-fired internal combustion units (diesel efficiencies can be as high as 40-50 per cent). However, natural gas units offer significant environmental and noise advantages.

Methane Escape Issues:

Although clean when burned, methane leakage can occur during the extraction, processing and transport of natural gas. Methane is a potent greenhouse gas with a much higher short-term greenhouse effect than carbon dioxide. Reducing methane escape throughout the supply chain is an important environmental issue.

High safety requirements:

Natural gas is flammable and explosive, and has very strict safety requirements for generator room design, ventilation, gas leak detection, fire protection systems, and operating procedures.

Main Application Scenarios

Distributed Energy: Installed near users (e.g. factories, hospitals, data centres, shopping malls, neighborhoods), it provides electricity and heat (CHP), improves energy efficiency, and enhances the reliability of energy supply.

Combined Heat and Power (CHP): Natural gas generators are the workhorses for efficient CHP.

Backup power: For places with stable piped gas supply and requirements for environmental protection and noise (e.g. hospitals, data centres, communication hubs, high-end buildings).

Baseload or peaking power: As clean baseload power or flexible peaking power in the grid (gas turbines are particularly suitable for peaking).

Utilisation of associated/unconventional gas: Generation of electricity from natural gas or biogas generated on-site at oil and gas fields, landfills, sewage treatment plants, etc.

Remote areas (when gas supply is available): As a main power source or important power source in remote areas where there are natural gas fields or where gas can be supplied via CNG/LNG.

Summary

The main features of natural gas generators are relatively clean and environmentally friendly, low operating noise, suitable for cogeneration, and advantageous operating costs in areas with stable gas sources. Its core strengths lie in its environmental friendliness and efficient cogeneration potential. However, it is highly dependent on gas supply infrastructure (especially pipelines), and the cost of using it where pipelines are not available can rise significantly. Initial investment costs are also typically high and there is a risk of gas price volatility. Choosing a natural gas generator requires a combination of local gas conditions, environmental requirements, initial investment budget, operating costs and the need for cogeneration.

In short: environmentally friendly, quiet, suitable for cogeneration, but ‘location-dependent’ (dependent on gas supply facilities).