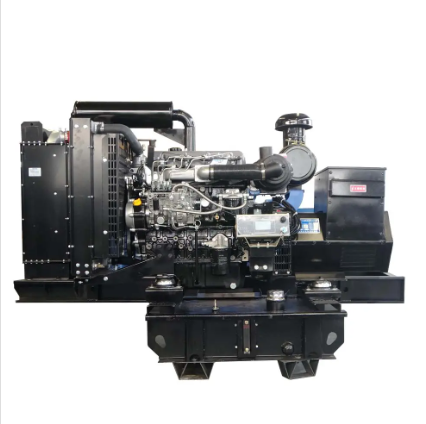

Ključni činioci koji treba uzeti u obzir prilikom uspoređivanja Dizel generatori

Efikasnost i potrošnja goriva

Ефикасност дизел генератора је веома важна јер нам показује колико се од скупог дизела заправо претвори у електричну енергију коју можемо користити. На простим терминима, то мери колики проценат горива на крају покреће наше машине, а не само загрева ваздух око себе. Већина дизел генератора има ефикасност између 10% и 25% у претварању горива у енергију. Упоредите то са новијим технологијама као што су чврсте оксидне горивне ћелије или на кратко SOFC, ове машине могу да постигну ефикасност између 40% и 60%. Сада је јасно зашто неке индустрије почињу да размишљају о алтернативама упркос почетним трошковима.

Количина горива коју дизел генератор потрошава зависи углавном од процента капацитета на којем ради и других фактора који утичу на перформансе. Узмимо као пример стандардну јединицу од 1 MVA. Када се генератор доведе до максималног излаза, потрошит ће око 225 kg дизел горива сваког сата и истовремено емитовати отприлике 720 kg угљен-диоксида. Шта се дешава када падне потражња? Математика постаје гора. На нижим оптерећењима, ове машине постају мање ефикасне, јер морају да наставе сагоријеване горива само да би остале у раду, чак и ако се не производи много енергије. Са инжењерске тачке гледишта, то има смисла, али ствара проблеме за све оне који су забринути због трошкова и еколошког утицаја.

Стручни радови из области енергетике често указују да генератори на дизел, иако су издржљиве израде, углавном троше више горива у поређењу са новијим моделима доступним на тржишту данас. Налажење правог баланса између добре потрошње горива и захтева операције у погледу електричне енергије остаје захтеван задатак. Компаније које разматрају различите опције генератора на дизел морају узети у обзир све ово, као и утицај на животну средину. На крају крајева, нико не жели да потроши додатна средства за гориво и истовремено непотребно допринесе емисији угљен-диоксида.

Izlazna snaga i skalabilnost

Дизел генератори долaze у свим величинама, што их чини добри за различите ситуације. То су и оне мале преносне верзије које производе можда 5 или 10 киловата, па све до индустријских монстара који могу да даду неколико мегавата. Различите величине значе да компаније не морају да бирају нешто што је превелико или премало за њихове потребе. Већина фирми има средње захтеве у погледу енергије, па овакав избор стварно помаже да се трошкови опреме ускладе са стварним потребама без превеликог напора на буџету.

Povećanje kapaciteta ističe se kao velika prednost dizel generatora. Zahvaljujući modularnom dizajnu, kompanije mogu jednostavno dodati više snage kada se posao širi. Na primer, gradilišta ili rudnici koji rade daleko od gradske mreže često se oslanjaju na dizel generatore jer imaju potrebu za fleksibilnim opcijama energije. Potrebe za snagom obično rastu kako projekti napreduju. Mnogi udaljeni rudarski pogoni zapravo su proširili svoje operacije dodavanjem dodatnih generatora po potrebi. Takvo skaliranje omogućava da sve ostane u funkciji čak i kada se operacija proširi izvan početnih planova. Mogućnost prilagođavanja izlazne snage čini dizel generatore posebno vrednim za poslovanje u nepredvidivim uslovima.

Primeri industrija koje koriste ovu skalabilnost uključuju građevinske kompanije koje postavljaju mobilne elektrane na mestu kako bi se postepeno povećao izlazni snaga po potrebi projekta, time ističući fleksibilnost dizel generatora u podršci rastu poslova.

Trajanje i životni vek

Трајање дизел генератора је заиста важно када се посматра њихова поузданост током времена и колико новца могу уштедети на дужи период. Ове машине су направљене да издрже, што значи да обично трају доста дуже од алтернатива које користе бензин. Већина људи који правилно одржавају своје дизел јединице може очекивати да ће радити где између 15.000 и око 50.000 радних сати пре него што буде потребно заменити их. Наравно, овај број варира у зависности од тога колико често генератор ради свакодневно и колико је редовно одржавање.

Autoritetni izveštaji sugeruju da dizel generatori, zahvaljujući svojim čvrstima motorima i nižem riziku isparkivanja, mogu održavati duže periode rada sa odgovarajućim održavanjem. Faktori kao što su redovne promene ulja, vremenski pregledi motora i brzo reagovanje na oštećenja ključni su za maksimizovanje njihovog života.

Preporuke za najbolje prakse u održavanju savetuju periodično serviranje i čuvanje dnevnika radnih sati kako bi se predvidelo kada će biti potrebno šire održavanje. Efikasna strategija održavanja ne samo štiti dugogodišnji život opreme, već i povećava njen pouzdanost, osiguravajući neprekinutu snabdevaču tokom ključnih operacija.

Dizel vs. Prirodni plin Generatori: Analiza performansi i cena

Uporedba efikasnosti

Efikasnost igra veliku ulogu kod odluke između dizel i generatora prirodnog gasa za većinu ljudi. Dizel agregati imaju bolju potrošnju goriva jer proizvode više energije iz svakog galona sagorelog goriva. Radi se o približno 20 do 40 posto boljoj učinakosti u različitim situacijama. Modeli na prirodni gas nisu tako efikasni, ali u celini ispuštaju manje zagađujućih materija. Stručnjaci za energiju slažu se da dizel mašine duže rade između punjenja rezervoara, što dugoročno čuva novac. S druge strane, cene goriva za generatore na prirodni gas su ponekad povoljnije na prvi pogled, ali zahtevaju češće održavanje i popravke koje na kraju povećavaju troškove. Deo vezan za održavanje je zapravo prilično značajan, jer ove instalacije zahtevaju posebne delove i periodične kontrole koje nisu uvek uključene u počene procene troškova.

Потребе за одржавање

Potrebe za održavanje dizel i generatora prirodnog gasa mogu značajno da utiču na troškove za preduzeća i na to koliko dobro oprema funkcioniše iz dana u dan. Za dizel agregate, obično je potrebno redovno menjati ulje, proveravati nivo rashladnog sredstva i čistiti ili zamenjivati vazdušne filtere kako bi sve normalno funkcionalisalo. Generatori na prirodni gas pričaju drugačiju priču. Pošto je prirodni gas znatno reaktivniji u odnosu na dizel gorivo, ovim generatorima je potrebno češće održavanje. Tehničari često moraju proveriti filtere goriva i svetlucave svećice bar dva puta češće nego kod dizel verzija. Prema raznim industrijskim izveštajima, većina preduzeća uočava da na duži rok troši više novca na održavanje sistema na prirodni gas. Stručnjaci za generatore stalno ukazuju na ovu tendenciju kada razgovaraju s menadžerima fabrika o dugoročnom planiranju. Kompanije koje žele da budu pripremljene za neočekivane troškove popravki treba da uzmu u obzir ove razlike prilikom izbora vrste goriva za rešenja za rezervno napajanje.

Еколошки утицај

Забринутост због еколошких ефеката дизел и природног гаса генератора наставља да расте, јер се прописи стално мењају у различитим регионима. Већ годинама дизел се повезује са много већим нивоима емисије угљен-диоксида, као и сумпор-диоксида и оних непријатних азотних оксида о којима сви често чујемо. Међутим, прелазак на природни гас чини заиста велику разлику. Ови алтернативни извори енергије производе око тридесет посто мање емисије CO2 и NOx, што одлично одговара захтевима које владе подстичу када нуде подстичаје за чистије горива. Ако погледамо стварна истраживања из области еколога, објекти који користе генераторе на природни гас често значајно смањују свој укупни угљенични отисак. Већина стручњака у индустрији сматра да ће наредне генерације генератора поставити још већи нагласак на смањење ових еколошких проблема. Зато многе компаније већ сада озбиљно разматрају могућност преласка на решења која користе природни гас за своје енергетске потребе.

Nastajuće alternative: Kako se hidrogen i SOFC generatori uspoređuju

Генератори на водоник (нпр. HyFlexâ¢)

Nastanak generatora na vodonik označava značajan napredak u načinu proizvodnje električne energije, donoseći prednosti poput veće efikasnosti i manjih štetnih emisija u poređenju sa tradicionalnim metodama. Međutim, činjenica je da skladištenje vodonika ostaje veliki problem za inženjere koji danas rade na ovoj tehnologiji. Uzmite za primer HyFlex – ovaj konkretni model je u poslednje vreme izazvao dosta pažnje jer testovi pokazuju da zaista prilično dobro funkcioniše kada se stavi na probu, i to i sa aspekta efikasnosti i sa aspekta emisije iz izduvne cevi. Ono što zaista uzbuđuje ljude kod sistema poput ovih je njihov potencijal da smanje našu zavisnost od nafte i gasa. Većina analitičara slaže se da bi vodonik mogao postati jedan od ključnih faktora u potrazi za čistijim izvorima energije, jednostavno zato što ne proizvodi gotovo toliko zagađujućih materija tokom rada i jer se može relativno lako skalirati u zavisnosti od potražnje.

Tehnologija Solid Oksid Dizel Celija (SOFC)

Tehnologija gorivnih ćelija sa solidnim oksidima postaje stvarna alternativa tradicionalnim dizel generatorima zahvaljujući boljim stepenima efikasnosti i znatno čistijim emisijama. Ovi SOFC generatori funkcionišu putem elektrohemije kako bi gorivo pretvorili u električnu energiju, i jednostavno nadmašuju dizel sisteme kada je u pitanju efikasno pretvaranje goriva. Ono što ih čini zanimljivim jeste mogućnost da rade na različita goriva, ne samo vodonik, već i danas. Istraživači su utvrdili da prirodni gas takođe prilično dobro funkcioniše, što otvara mogućnosti za praktičnu primenu već sada. Oblast je nedavno postigla značajan napredak, što ukazuje na bolju budućnost za opcije zelene energije. Iako još uvek postoji posao koji treba obaviti pre nego što dođe do široke primene, ove ćelije mogu preoblikovati određene delove energetskog sektora ukoliko proizvođači budu u stanju da povećaju proizvodnju bez prevelikih troškova.

Primene i slučajevi upotrebe za Dizel generatori

Gradilišta i udaljena mesta

Na gradilištima i na teško dostupnim mestima, dizel agregati su skoro nužni kada je u pitanju pouzdan izvor energije. Dovoljno su prenosivi da se mogu premeštati po gradilištu i dovoljno moćni da održe rad svih teških mašina, kao i osvetljenje gradilišta noću. Stručnjaci iz industrije navode da oko 70% gradjevinskih radova zaista zavisi od ovih dizel jedinica za svoje energetske potrebe, posebno u područjima gde nema povezivanja sa električnom mrežom. Razmislite sa bilo kojim izvođačem koji je radio na putevima u planinama ili razvojnim projektima u pustinjama i oni će vam pričati kako ovi dizel sistemi spasavaju situaciju kada se radi na zahtevnim terenima. Činjenica je da bi mnogi projekti stali da se izvode, bez obzira na lokaciju, kada ne bi bilo ovih generatora.

Rezervna snaga za hitne situacije za bolnice/podatkovne centre

Болнице и центри за обраду података у великој мери се ослањају на дизел генераторе као извор резервне енергије када главна мрежа престане да ради. Ови агрегати прелазе у рад довољно брзо да се операције одржавају без прекида у местима где није дозвољено да дође до квара. Замислите операционе сале у којима светлост мора остати укључена док некој особи зависи живот од тога, или сервере који чувају огромне количине информација који не смеју да оду офлајн. Током велике енергетске кризе у Тексасу 2021. године, ови генератори су буквално спасили ситуацију за многе медицинске установе и технолошке компаније. Медицинске институције не бирају генераторе ни на основу случајности. Постоје строга правила која регулишу које системе резервног напајања је дозвољено инсталирати, пре свега зато што су животи пацијената у питању, а скупоцена опрема заштићена од изненадних губитака струје.

Industrijske i marinske primjene

Дизел генератори се појављују свуда, од фабрика до бродова, доказујући своју незаменљивост у многим различитим контекстима. На копну, произвођачи се ослањају на њих за покретање производних линија и напајање великих машина зато што су увек доступни када су најпотребнији. На мору, бродски оператори рачунају на дизел погон за рад навигационих система, осветљења и других критичних функција током дугих путовања када поновно пуњење горивом није увек могуће. Бродски сектор је остао при дизел моторима и због добрих разлога – ови мотори могу да издрже тешке оптерећења без кварова. Иако неке еколошке групе заговарају чистије алтернативе, инжењери који раде са дизел технологијом настављају да побољшавају стандарде ефикасности како би бродови могли да испуне строжија правила о емисијама без изгубљења перформанси. Већина механичара са којима сам разговарао и даље сматра дизел најсигурнијом опцијом, упркос свим дискусијама о зеленим енергијама.

Izbor odgovarajućeg dizelskog generatora za vaše potrebe

Procena potreba za snagom

Izbor odgovarajuće dizel agregat počinje analizom kakvih su zahteva za energiju u okviru određene operacije, uz pravilno izračunavanje opterećenja. Tačno određivanje ovih parametara je izuzetno važno, jer poznavanje količine električne energije koju različiti procesi troše omogućava održavanje efikasnosti sistema i sprečava mogućnost preopterećenja. Zahteve za snagom moguće je izmeriti različitim metodama, uključujući korišćenje specijalizovanih kalkulatora dizajniranih za tu svrhu ili kontaktiranje kvalifikovanih elektro inženjera koji potpuno razumeju specifikacije u kilovatima. Na primer, većina manjih prodajnih objekata uspešno funkcioniše sa generatorima od oko 10 kW, dok industrijske radionice često zahtevaju znatno moćnije jedinice koje mogu da obezbede stotine kilovata zbog složenih potreba mašinerije. Prilagođena rešenja u pogledu snabdevanja energijom nude stvarne prednosti, omogućavajući kompanijama da bolje upravljaju potrošnjom energije i postepeno smanje nepotrebne troškove, a da pritom ne žrtvuju pouzdanost u ključnim trenucima.

Procena raspoloživosti goriva

Лакоћа добијања горива има велику улогу у избору праве дизел генераторске опреме за посао, утичући на све аспекти, од свакодневног рада до дугорочног планирања. Нека подручја имају бољи приступ дизел гориву него друга, што чини сву разлику на свету за предузећа која на том месту користе генераторе. Компаније које су удаљене од главних путева или су у тешко приступачним теренима често морају да развију добре планове за набавку горива, како не би остале без њега у тренуцима када је најнеопходније. Узмимо као пример мали фабрички објекат у неком сеоском подручју. Они би могли да се упишу у програм сталних испорука горива путем уговора са достављачем, како би осигурали непрекидан рад. Постојање оваквих уговорних аранжмана значи стабилну испоруку горива, чиме се одржава рад и у периодима када је гориво теже доступно, уколико до тога дође у одређеним сезонама или у непредвиђеним околностима.

Буџет и дугорочни трошкови

Kada posmatraju dizel generatore, kompanije moraju da izmere ono što plate unapred naspram onoga što će potrošiti tokom vremena. Naravno, cena može delovati visoko na prvi pogled, ali razmišljanje o uštedama koje se ostvaruju kroz veću efikasnost i duži vek trajanja potpuno menja sliku. Finansijski stručnjaci ukazuju na sve vrste dodatnih troškova koji se često prikradaju – redovne servisne preglede, potrošnju goriva, takve stvari zaista iscrpljuju krajnji rezultat. Pametno planiranje budžeta za bilo koju organizaciju koja se odlučuje za dizel obično znači temeljno ispitivanje ovih dodatnih troškova, uz istovremeno praćenje mogućih poreskih olakšica povezanih sa praksama u oblasti zelene energije. Pravilan pristup ovome omogućava kompanijama da zadrže troškove pod kontrolom i izaberu opcije napajanja koje će u stvarnosti zaista dobro funkcionišati za njih.

Често постављана питања

Koje su glavne prednosti dizel generatora?

Dizel generatori nude efikasnost, skalabilnost, trajnost i širok raspon snaga koji su pogodni za različite primene, čime postaju idealni za preduzeća koja traže pouzdanu energetsku rešenja.

Kako se dizel generatori uspoređuju sa generatorima na prirodnim plinom?

Dizel generatori su općenito efikasniji i ekonomičniji za produžene operacije, dok generatori na prirodan plin nude niže emisije, ali mogu zahtevati češću održavanja i imati više operativnih troškova.

Zašto se dizel generatori više koriste u gradjevinarstvu i udaljenim lokacijama?

Dizel generatori su prijenosni, pouzdani i sposobni da pružaju značajan izlaz snage, što je ključno za gradilišta i udaljene lokacije gde je pristup mreži ograničen.

Šta bi tvrtke trebale uzeti u obzir prilikom biranja dizel generatora?

Ključne razmatranja uključuju procenu potreba za snagom, evaluaciju raspoloživosti goriva, razumevanje proračuna i dugoročnih troškova, kao i planiranje za održavanje kako bi se osigurala efikasna radnja.

Koje buduće trendove utiču na tehnologiju generatora?

Nalazeće se tehnologije poput vodonikovog i SOFC generatora fokusiraju se na povećanje efikasnosti i smanjenje emisija, položavajući se kao održive alternative tradicionalnim dizel generatorima.

Садржај

- Ključni činioci koji treba uzeti u obzir prilikom uspoređivanja Dizel generatori

- Dizel vs. Prirodni plin Generatori: Analiza performansi i cena

- Nastajuće alternative: Kako se hidrogen i SOFC generatori uspoređuju

- Primene i slučajevi upotrebe za Dizel generatori

- Izbor odgovarajućeg dizelskog generatora za vaše potrebe

-

Често постављана питања

- Koje su glavne prednosti dizel generatora?

- Kako se dizel generatori uspoređuju sa generatorima na prirodnim plinom?

- Zašto se dizel generatori više koriste u gradjevinarstvu i udaljenim lokacijama?

- Šta bi tvrtke trebale uzeti u obzir prilikom biranja dizel generatora?

- Koje buduće trendove utiču na tehnologiju generatora?