Maximizing Performance Through Proper Generator Care

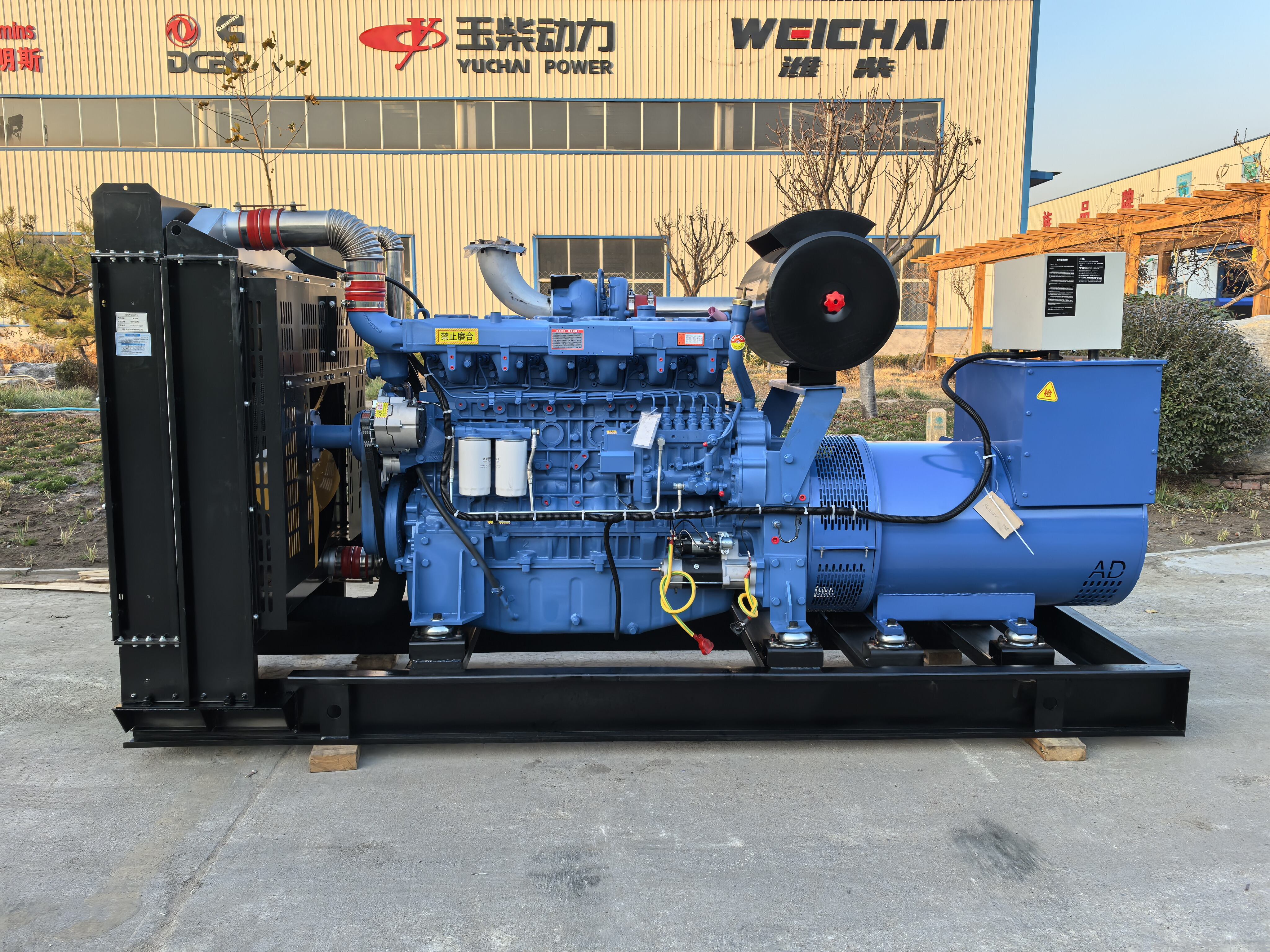

When it comes to reliable backup power solutions, a diesel power generator stands as the cornerstone of operational continuity for countless businesses and facilities worldwide. The robust nature of these machines, combined with their fuel efficiency and long service life, makes them an invaluable asset. However, achieving optimal performance and longevity requires a well-structured maintenance approach that addresses every critical component.

Understanding the fundamentals of generator maintenance not only ensures consistent operation but also significantly reduces the risk of unexpected breakdowns. Whether you're managing a data center, healthcare facility, or industrial complex, the importance of maintaining your diesel power generator cannot be overstated.

Core Maintenance Components

Fuel System Management

The heart of any diesel power generator lies in its fuel system. Regular fuel quality checks are essential to prevent contamination and ensure optimal performance. Implementing a fuel testing schedule helps identify potential issues such as water contamination, microbial growth, or sediment accumulation. Best practices include maintaining fuel tanks at least 75% full to minimize condensation and scheduling periodic fuel polishing services.

Fuel filters require particular attention, as they prevent contaminants from reaching critical engine components. Establishing a regular replacement schedule based on operating hours and environmental conditions helps maintain fuel system integrity. Additionally, monitoring fuel consumption patterns can provide early warning signs of potential system inefficiencies.

Engine Oil Management

The lifeblood of your diesel power generator is its engine oil. Maintaining proper oil levels and quality directly impacts engine longevity and performance. Regular oil analysis provides valuable insights into engine health and helps detect potential issues before they become critical problems. Implementing an oil change schedule based on manufacturer recommendations and operating conditions ensures optimal engine protection.

When selecting engine oil, consider the specific requirements of your generator model and operating environment. Premium-grade oils designed for heavy-duty diesel engines often provide superior protection and extended service intervals. Keep detailed records of oil changes, analysis results, and consumption patterns to track engine health over time.

Environmental Considerations

Temperature Control Systems

Maintaining optimal operating temperature is crucial for diesel power generator reliability. The cooling system must be regularly inspected and maintained to prevent overheating. This includes checking coolant levels, inspecting hoses for wear or damage, and ensuring proper functioning of the radiator and fan systems.

Environmental factors such as ambient temperature and altitude can significantly impact cooling system requirements. Installing temperature monitoring systems and maintaining proper ventilation in the generator room helps prevent heat-related issues. Regular cleaning of cooling fins and heat exchangers ensures efficient heat dissipation.

Air Filtration Management

Clean air intake is essential for efficient combustion and engine protection. Regular inspection and replacement of air filters prevent abrasive particles from entering the engine. In dusty environments, more frequent filter changes may be necessary to maintain optimal performance.

Consider implementing a differential pressure monitoring system to track air filter condition and optimize replacement intervals. Proper sealing of the air intake system prevents unfiltered air from bypassing the filtration system, protecting critical engine components.

Electrical System Maintenance

Battery Care Protocols

The starting system of a diesel power generator relies heavily on battery performance. Regular battery maintenance includes checking electrolyte levels, terminal connections, and charging system operation. Implement a battery testing schedule to ensure reliable starting capability when needed.

Modern maintenance practices include using battery monitoring systems that provide real-time status updates and early warning of potential failures. Keeping battery terminals clean and properly torqued prevents connection issues that could lead to starting failures.

Generator End Maintenance

The alternator component of your diesel power generator requires specific attention to ensure reliable power output. Regular inspection of brushes, slip rings, and windings helps identify potential issues before they affect performance. Maintaining proper alignment between the engine and generator prevents excessive vibration and bearing wear.

Implementing a regular testing schedule that includes load bank testing ensures the generator can deliver rated power when needed. Monitor voltage regulation and frequency stability during testing to verify proper operation under various load conditions.

Preventive Maintenance Scheduling

Documentation Systems

Maintaining detailed records of all maintenance activities provides valuable historical data for troubleshooting and planning. Implement a comprehensive documentation system that tracks maintenance intervals, part replacements, and performance metrics. This information helps optimize maintenance schedules and predict potential issues before they occur.

Digital maintenance management systems can automate scheduling and provide reminders for upcoming maintenance tasks. These systems also help track inventory of critical spare parts and maintenance supplies, ensuring availability when needed.

Professional Service Integration

While many maintenance tasks can be performed in-house, partnering with qualified service providers ensures access to specialized expertise and diagnostic tools. Professional technicians can perform comprehensive inspections and adjustments that may be beyond the capability of facility staff.

Establishing a relationship with a reliable service provider ensures prompt response during emergencies and access to genuine replacement parts. Regular professional inspections complement in-house maintenance efforts and help maintain warranty coverage.

Frequently Asked Questions

How often should I change the oil in my diesel power generator?

Oil change intervals typically range from 250 to 500 operating hours, depending on the generator model, operating conditions, and oil type used. However, regular oil analysis should guide your specific maintenance schedule, as it provides actual data about oil condition and engine health.

What are the signs that indicate potential generator problems?

Key warning signs include unusual noise or vibration, excessive smoke, reduced power output, increased fuel consumption, or difficulty starting. Regular monitoring of these parameters helps identify potential issues early, allowing for proactive maintenance intervention.

How can I ensure my diesel power generator starts reliably in cold weather?

Cold weather reliability depends on maintaining proper battery condition, using appropriate oil viscosity, and ensuring the fuel system is free of water contamination. Installing and maintaining block heaters and battery warmers can significantly improve cold-weather starting reliability.