Key Factors to Consider When Comparing Diesel Power Generators

Efficiency & Fuel Consumption

The efficiency of diesel power generators matters a lot because it tells us how much of that precious diesel actually gets turned into electricity we can use. Simply put, this measures what percentage of the fuel ends up powering our equipment rather than just heating up the air around it. Most diesel generators sit somewhere between 10% and 25% efficient when converting fuel to power. Compare that to newer technologies like Solid Oxide Fuel Cells or SOFCs for short, these babies manage to squeeze out anywhere from 40% to 60% efficiency. Makes sense why some industries are starting to look at alternatives despite the upfront costs.

How much fuel a diesel generator burns depends heavily on what percentage of capacity it's working at and other factors affecting performance. Take a standard 1 MVA unit for example. When pushed to maximum output, such a generator will burn about 225 kg of diesel each hour while pumping out roughly 720 kg worth of carbon dioxide emissions as well. What happens though when demand drops? The math gets worse actually. At lower loads, these machines become less efficient because they still need to keep burning fuel just to stay running even if there isn't much power being generated. This makes sense from an engineering standpoint but creates problems for anyone concerned about both costs and environmental impact.

Energy research papers often point out that diesel generators, even though they are built tough, generally burn through more fuel compared to newer models on the market today. Finding the right mix between getting good fuel economy and meeting what the operation actually needs for power remains tricky business. Companies looking at different diesel generator choices need to think about all this plus how their choice affects the environment too. After all, nobody wants to spend extra money on fuel while also contributing unnecessarily to carbon emissions.

Power Output & Scalability

Diesel generators come in all sorts of sizes, which makes them work well across different situations. We're talking everything from those little portable models that put out maybe 5 or 10 kilowatts right up to industrial beasts capable of cranking out multiple megawatts. The size options mean companies don't have to settle for something too big or too small for what they need. Most businesses find themselves somewhere in the middle when it comes to power demands, so having this range really helps match equipment costs with actual usage needs without breaking the bank.

Scalability stands out as a major plus for diesel generators. With a modular design, companies can simply add more power when business grows. Take construction sites or mines operating far from city grids, these places frequently rely on diesel generators because they need flexible power options. Power requirements tend to climb as projects progress. Many remote mining operations have actually expanded by bringing in extra generator units as needed. This kind of scaling keeps everything running smoothly even when the operation expands beyond initial plans. The ability to adjust power output makes diesel generators particularly valuable for businesses working in unpredictable conditions.

Examples of industries leveraging this scalability include construction companies that set up mobile power stations on-site to gradually increase power output as project demands grow, thus highlighting the flexibility of diesel generators in supporting business growth.

Durability & Lifespan

How long diesel generators last really matters when looking at how reliable they are over time and what kind of money they save in the long run. These machines are built tough, which means they tend to outlast gas powered alternatives by quite a bit. Most folks who take care of their diesel units can expect them to run anywhere from 15 thousand to around 50 thousand hours before needing replacement. Of course this number varies based on how hard the generator works day to day and just how regular the maintenance schedule happens to be.

Authoritative reports suggest that diesel generators, due to their robust engines and lower spark risk, can sustain longer periods of operation with proper maintenance. Factors such as regular oil changes, timely engine inspections, and addressing wear and tear promptly are crucial for maximizing their lifespan.

Maintenance best practices recommend periodic servicing and keeping a log of operating hours to anticipate when more extensive servicing might be necessary. An effective maintenance strategy not only ensures the longevity of the equipment but also enhances its reliability, securing continuous power supply during critical operations.

Diesel vs. Natural Gas Generators: Performance and Cost Analysis

Efficiency Comparison

Efficiency matters a lot when deciding between diesel and natural gas generators for most people. Diesel units tend to get better fuel economy because they generate more power from each gallon burned. We're talking around 20 to 40 percent better performance across different situations. Natural gas models aren't as efficient but do emit fewer pollutants overall. Energy experts agree that diesel machines run longer between refuels which saves money over time. On the flip side, natural gas generators sometimes have cheaper fuel prices at first glance, but they need more regular upkeep and repairs that drive up expenses eventually. The maintenance part is actually pretty significant since these systems require special parts and periodic checks that aren't always included in initial cost estimates.

Maintenance Requirements

The maintenance needs of diesel versus natural gas generators can make a real difference in what companies spend and how well their equipment runs day to day. For diesel units, folks usually need to change the oil regularly, check coolant levels, and clean or replace air filters so everything keeps running smoothly. Natural gas models tell a different story though. Because natural gas is so much more reactive than diesel fuel, these generators need attention more often. Technicians end up checking fuel filters and spark plugs at least twice as frequently as they would with diesel counterparts. According to various industry reports, most businesses find themselves spending more money maintaining natural gas systems over time. Generator specialists consistently point out this trend when talking to plant managers about long term planning. Companies that want to stay ahead of unexpected repair bills should factor in these differences when choosing between fuel types for their backup power solutions.

Environmental Impact

Concern about the environmental effects of diesel and natural gas generators keeps rising as regulations continue changing across different regions. For years now, diesel has been linked to much higher levels of carbon emissions along with sulfur dioxide and those nasty nitrogen oxides we all hear so much about. Switching to natural gas makes a real difference though. These alternatives produce around thirty percent fewer CO2 and NOx emissions, which fits well with what governments are pushing for when they offer incentives for cleaner fuels. Looking at actual research from environmental scientists, facilities that go with natural gas generators tend to slash their overall carbon footprint quite substantially. Most industry experts believe that coming generations of generators will place even greater emphasis on reducing these environmental problems. That's why many companies are already starting to look seriously at switching over to natural gas solutions for their power requirements.

Emerging Alternatives: How Hydrogen and SOFC Generators Stack Up

Hydrogen-Powered Generators (e.g., HyFlexâ¢)

The rise of hydrogen powered generators marks a significant advancement in how we generate electricity, bringing with them advantages like better efficiency rates and fewer harmful emissions compared to traditional methods. But there's no getting around the fact that storing all that hydrogen remains a major headache for engineers working on this technology today. Take HyFlex for instance – this particular model has been generating quite a buzz lately because tests show it actually works pretty well when put through its paces, both from an efficiency standpoint and looking at what comes out of the exhaust pipe. What really excites people about systems like these though is their potential to cut down our dependence on oil and gas altogether. Most analysts agree that hydrogen could become one of those game changers in the quest for cleaner energy sources simply because it doesn't produce nearly as many pollutants during operation and can scale up relatively easily depending on demand.

Solid Oxide Fuel Cell (SOFC) Technology

Solid oxide fuel cell technology is becoming a real alternative to old school diesel generators thanks to better efficiency rates and much cleaner emissions. These SOFC generators work through electrochemistry to turn fuel into electricity, and they just plain outperform diesel systems when it comes to converting fuel efficiently. What makes them interesting is their ability to run on different fuels beyond just hydrogen these days. Researchers have found that natural gas works pretty well too, which opens up some practical applications right now. The field has made good progress lately, pointing toward a brighter future for green power options. While there's still work to do before widespread adoption happens, these cells could reshape parts of the energy sector if manufacturers can scale production without breaking the bank.

Applications and Use Cases for Diesel Power Generators

Construction Sites & Remote Locations

On construction sites and out in those hard-to-reach spots, diesel generators are pretty much a necessity when it comes to having dependable power. They're portable enough to move around the site and pack enough punch to keep all the heavy machinery running while also lighting up the worksite at night. Industry folks say somewhere around 70% of construction jobs actually depend on these diesel units for their power needs, particularly where there's no electricity grid nearby. Talk to any contractor who's worked on mountain roads or desert developments and they'll tell stories about how these diesel setups save the day when dealing with tough terrain. The truth is, without these generators, many projects would come grinding to a halt no matter where they happen to be located.

Emergency Backup Power for Hospitals/Data Centers

Hospitals and data centers rely heavily on diesel generators as backup power sources when the main grid goes down. These machines kick in fast enough to keep things running smoothly in places where failure isn't an option at all. Think about surgical suites needing lights while someone's life depends on it, or servers storing massive amounts of information that just can't go offline. During the big Texas power crisis back in 2021, these generators literally saved the day for many healthcare providers and tech companies alike. Medical facilities aren't just picking generators randomly either. There are strict rules governing what kind of backup systems get installed, mainly because patients' lives hang in the balance and expensive equipment needs protection from sudden power losses.

Industrial & Marine Applications

Diesel generators show up everywhere from factories to ships, proving themselves indispensable in many different contexts. On land, manufacturers depend on them for running production lines and powering big machines because they just keep going when needed most. Out at sea, ship operators count on diesel power to run navigation systems, lighting, and other critical functions during long trips where refueling isn't always possible. The shipping industry has stuck with diesel for good reason too - these engines handle tough workloads without breaking down. While some environmental groups push for cleaner alternatives, engineers working with diesel tech continue improving efficiency standards so vessels can comply with stricter emissions rules without sacrificing performance. Most mechanics I've spoken to still see diesel as the workhorse option despite all the talk about green energy solutions.

Choosing the Right Diesel Generator for Your Needs

Assessing Power Requirements

Selecting the appropriate diesel generator begins by looking at what kind of power demands exist within any given operation along with proper load calculations. Getting this right matters a lot since knowing precisely how much electricity different processes consume helps maintain system efficiency while preventing potential overload situations. Power requirements can be measured through various means including specialized calculators designed for such purposes or simply reaching out to qualified electrical engineers who understand kW specifications inside out. For instance, most small retail outlets typically operate fine with around 10 kW generators, but industrial facilities often need massive units capable of handling hundreds of kilowatts due to their complex machinery needs. Customized power setups offer real advantages though, allowing companies to manage their energy consumption better and cut down on unnecessary expenses over time without sacrificing reliability when it counts most.

Evaluating Fuel Availability

How easy it is to get fuel plays a big role in picking the right diesel generator for the job, affecting everything from day-to-day operations to long term planning. Some places just have better access to diesel fuel than others do, which makes all the difference in the world for businesses running generators there. Companies located far away from main roads or in tough terrain usually find themselves needing good plans for getting fuel so they don't run out of gas when they need it most. Take a small factory somewhere rural, for example. They might sign up for regular deliveries through a fuel supplier agreement to keep things running smoothly. Having these kinds of arrangements in place means steady fuel coming in, which keeps operations going even when fuel becomes harder to find in certain seasons or under unexpected circumstances.

Budget and Long-Term Costs

When looking at diesel generators, companies need to weigh what they pay upfront against what they'll spend over time. Sure, the price tag might look steep at first glance, but thinking about how much money gets saved through better efficiency and longer lifespan changes things completely. Financial experts point out all sorts of extra expenses that tend to sneak up on people too - regular maintenance checks, fuel consumption rates, those kinds of things really eat into the bottom line. Smart budgeting for any organization wanting to go with diesel usually means digging deep into these extra costs while also keeping an eye out for possible tax breaks related to green energy practices. Getting this right allows companies to keep their spending under control and pick power options that actually work well for them in the real world.

FAQ

What are the main advantages of diesel power generators?

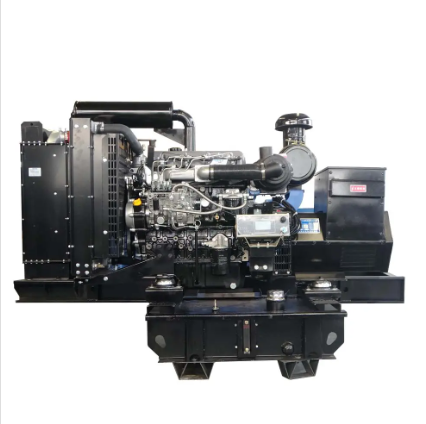

Diesel power generators offer efficiency, scalability, durability, and a wide range of power outputs suitable for diverse applications, making them ideal for businesses needing reliable power solutions.

How do diesel generators compare to natural gas generators?

Diesel generators are generally more efficient and cost-effective for extended operations, whereas natural gas generators offer lower emissions but may require more frequent maintenance and have higher operational costs.

Why are diesel generators preferred in construction and remote locations?

Diesel generators are portable, reliable, and capable of delivering significant power output, essential for construction sites and remote locations where grid access is limited.

What should businesses consider when choosing a diesel generator?

Key considerations include assessing power needs, evaluating fuel availability, understanding budget and long-term costs, and planning for maintenance to ensure efficient operations.

What future trends are influencing generator technology?

Emerging technologies like hydrogen-fueled and SOFC generators focus on increasing efficiency and reducing emissions, positioning themselves as sustainable alternatives to traditional diesel generators.

Table of Contents

- Key Factors to Consider When Comparing Diesel Power Generators

- Diesel vs. Natural Gas Generators: Performance and Cost Analysis

- Emerging Alternatives: How Hydrogen and SOFC Generators Stack Up

- Applications and Use Cases for Diesel Power Generators

- Choosing the Right Diesel Generator for Your Needs

-

FAQ

- What are the main advantages of diesel power generators?

- How do diesel generators compare to natural gas generators?

- Why are diesel generators preferred in construction and remote locations?

- What should businesses consider when choosing a diesel generator?

- What future trends are influencing generator technology?